top of page

Lightweight Design of Driveline Flange

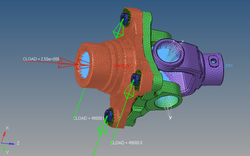

Conducted lightweight design of driveline flange based the CAE analysis, decreasing the weight of the flange by 45%.

• Simplified driveline mechanisms by analyzing loading and boundary conditions, then established CAD models and CAE mesh work in HyperMesh

• Analyzed the worst loading condition on flange, simulated this case in ABAQUS to evaluate the stress distributions

• Cut down materials on low stress area, remodeled flange in UG NX and calculated the mass reduction

• Verified new design in structural durability performance by checking the stress level in ABAQUS

Skills: UG NX, Hypermesh, Abaqus,Material Mechanics, Mechanical Optimization, GD&T

Step1: NX Modeling |  Step2: Hypermesh ModelingSimplified driveline mechanisms by analyzing loading and boundary conditions, then established CAD models and CAE mesh work in HyperMesh |  Step3: Abaqus SimulationAnalyzed the worst loading condition on flange, simulated this case in ABAQUS to evaluate the stress distributions |

|---|---|---|

Step4:Opitimized NX ModelingCut down materials on low stress area, remodeled flange in UG NX and calculated the mass reduction |  |  Step5:CAE VerificationVerified new design in structural durability performance by checking the stress level in ABAQUS |

bottom of page